Overview

Epoxy flooring is a resinous floor coating designed to be applicable in many different environments. From homes to businesses to industrial facilities, this versatile flooring system can be found almost anywhere. According to Epoxy Flooring Technologies, epoxy floor coatings, as we know them today, were made in 1936. They were initially applied commercially in Aerospace technologies. Over the course of several decades, these resinous coatings expanded into other commercial and industrial applications, such as warehouse and factory floor coatings.

What is Epoxy?

Epoxy is an adhesive, resinous material created as a polymer of epoxides. According to Thermal-Chem, the name epoxy is used to describe coatings made from two components. This means a combined mix of two different chemicals, called resin. The resin is composed of short-chain polymers, which contain an epoxide group. This combination classifies epoxy as a copolymer. Epoxy is known to be the strongest resin in the industry.

Applications

Modern epoxy flooring is used in a vast amount of varying applications. These include residential, commercial, and industrial applications. As a result of the high customization this concrete coating offers, it can be altered to fit each application’s specific needs.

Residential Epoxy Flooring

Many homeowners have switched from traditional flooring systems like carpet, hardwood, and tile in favor of epoxy flooring. With the various styles, colors, patterns, and textures that epoxy is available in, homeowners typically customize these floors to match the home’s decor, personalize rooms, and fit functional spaces, such as workshops and garages. Below, you can see some of the most common residential applications for epoxy flooring:

- Garage Flooring

- Kitchen Flooring

- Basement Flooring

- Living Room Flooring

Those were some of the most popular applications. However, epoxy flooring can be installed in any room in the home with a suitable substrate, such as concrete. It’s not uncommon to find epoxy flooring in bathrooms, bedrooms, sunrooms, and more

Commercial Epoxy Flooring

Epoxy flooring has since grown exponentially in the commercial industry. There are many businesses that have opted for this flooring solution in lieu of conventional floors, such as bare concrete or VCT. Below are the most common locations for commercial epoxy flooring applications:

- Retail Stores

- Grocery Stores

- Malls

- Hospitals

- Restaurants

- Auto Shops

- Schools

- Showrooms

- Nursing Homes

- Hotels

Epoxy flooring is seeing use throughout the commercial industry. Recently, the marijuana industry has also started converting to epoxy floors for grow facilities due to the benefits it provides.

Industrial Epoxy Flooring

Epoxy flooring got its real start in the industrial sector, first with aerospace applications and then to factories and other industrial facilities. Epoxy flooring has been present in industrial applications for decades. Below are the most common industrial locations for epoxy flooring applications:

- Factories

- Distribution Centers

- Warehouses

- Airplane Hangars

- Manufacturing Plants

- Cold Storage Buildings

- Data Centers

Thanks to the years that epoxy flooring has already been established in the industrial sector, it has managed to find its way into almost every aspect of industrial applications.

The Types of Epoxy Flooring

There are several types and styles of epoxy flooring to choose from today. As for types, according to Floorguard, virtually all professional-grade epoxy floors are 100% solids epoxy. Water-based epoxy and solvent-based epoxy are the other two types. Typically, water-based epoxies are what’s found in the DIY epoxy flooring kits. These epoxies are best utilized for thin coatings or epoxy paints rather than flooring. Solvent-based epoxies have all but been filtered out over recent years. This is due to the high amount of VOCs or Volatile Organic Compounds found in these epoxy coatings. Solvent-based epoxies were typically set aside for industrial applications.

Below, you can see the various styles of epoxy flooring:

Standard Epoxy Flooring

One of the most common epoxy flooring styles is standard epoxy. Usually, if an epoxy floor is mentioned, this is the type being referred to. Standard epoxy flooring is available in many different colors, from earth tones to bright, vibrant hues. A wide variety of patterns can be formed with standard epoxy as well, such as tiled patterns, geometric designs, or floral designs. However, standard epoxy is also commonly applied as a solid-color floor.

Metallic Epoxy Flooring

Metallic epoxy flooring is widely considered one of the most unique flooring systems available. These epoxy floors are made by mixing metallic pigments into the resin during the application process. These metallic pigments give the floor a shimmering appearance that can be shaped to create various patterns. The most popular design for metallic epoxy is a colorful, swirling pattern unique to each floor it’s applied to. This epoxy flooring style can also mimic scenes from nature, such as lava, water, and the sky.

Decorative Flake Epoxy Flooring

Decorative flake epoxy flooring is utilized for both aesthetic and functional purposes by home and business owners. This epoxy style is created by layering decorative flakes over the base epoxy layer before finishing the floor with a thin topcoat. The acrylic chips give the floor texture, which can aid in slip-resistance while giving the floor a look similar to terrazzo flooring. These decorative flakes come in various colors, shapes, and sizes, ranging from 1/16 to 1 inch.

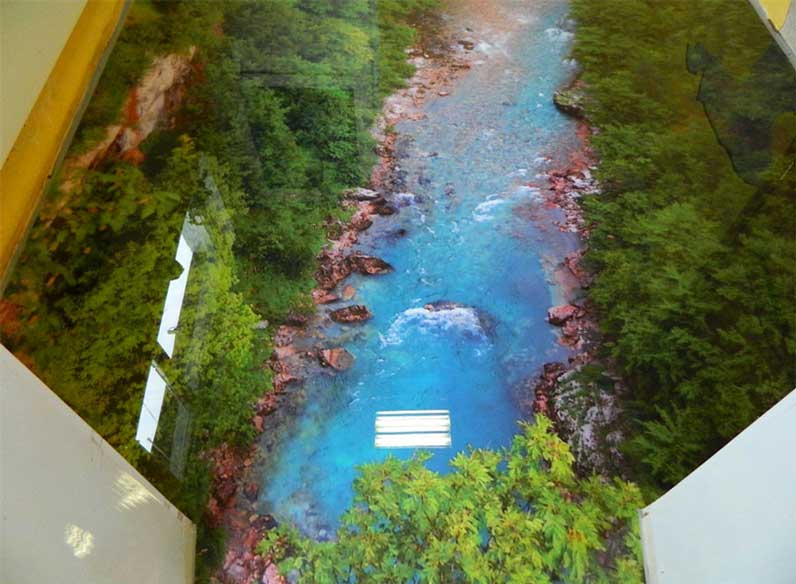

3D Epoxy Flooring

Flooring decals have been popular for years. Traditionally, they’re installed directly onto the existing floor’s surface. Essentially, the same concept is applied to 3D epoxy flooring with a twist. The decal is installed over the epoxy base and is coated with a thick, clear epoxy topcoat. This application method gives the image depth and enhances its realism, thus earning the name “3D epoxy.” Many images are popular with 3D epoxy flooring. Some of these include underwater scenes, wooded displays, and space themes.

Epoxy Flooring with Logos

Applying a logo to an epoxy floor is quite similar to the 3D epoxy process. The installation is the same, except the image is typically a brand logo, sports team, or even family names. Epoxy flooring with logos can apply to any of the epoxy flooring styles mentioned above.

Special Epoxy Flooring

Special epoxy flooring applies to any epoxy floor that’s out of the regular categories we’ve mentioned. This includes penny epoxy floors, vinyl record epoxy floors, bottlecap epoxy floors, and glitter epoxy floors. Penny, vinyl record, and bottlecap epoxy floors are made by layering the chosen item over the base epoxy layer, similarly to decorative flake epoxy flooring and finishing it with the epoxy topcoat. The glitter epoxy floors are made much like metallic epoxy floors. The main difference between the two being that glitter is used in place of metallic pigments. Special epoxy floors are usually made with something sentimental to the home or business owner.

The Epoxy Flooring Installation Process

The installation of professional-grade epoxy flooring should always be handled by a trained, licensed professional. According to Concrete Contractors, these floor coatings require specific steps that need attention to detail and various heavy equipment to complete correctly.

Cleaning and Inspecting the Concrete

The first step in the epoxy flooring installation process is cleaning and inspecting the base concrete for damage. All significant flaws in the concrete will need to be prepared before moving forward. Minor wear, such as pits or small holes, can be left until the next step. However, damage like cracks, gouges, or chipped areas will need repairing. Repairs will generally be completed using an injectable epoxy crack filler and a powdered concrete patch for gouges and chipped areas.

Floor Preparation

The next step is prepping the floor for the epoxy mixture. This step removes the previously mentioned minor blemishes while ensuring the epoxy resin adheres to the concrete substrate properly. There are two commonly used options for prepping the floor. The first option is using a floor grinder equipped with a coarse, diamond grinding wheel to grind the concrete’s outer layer, leveling it, removing blemishes, and making the surface more porous for the epoxy to adhere. The second option is using a shot blaster to blast away the outer layer of concrete. This option isn’t as popular as it’s less efficient compared to the floor grinder. After the grinding or shot blasting is finished, a moisture check is performed on the concrete to ensure optimal levels for the epoxy application.

Applying the Epoxy

With the floor prepped, the epoxy can be applied. A coat of epoxy primer is applied first. While the primer dries, the epoxy is mixed with a urethane hardener and spread over the dried primer. Each mixed batch of epoxy has a time limit to be applied, so more than one person is usually needed to apply the epoxy resin. Typically, one base coat is necessary before any type of customization can be installed. Once the base has been poured, any patterns, metallic pigments, decorative flakes, or decals can be created, mixed, or set. The epoxy layers will need to dry for a few hours before the topcoat can be placed to seal everything in place. With the sealer in place, the epoxy floor needs 72 hours to cure and be ready for full use.

Installation Timeline

In most cases, it takes 1 to 2 days to install an epoxy floor. This timeline can vary, depending on several factors, such as design complexity, temperature, and the size of the room or building. Here is a timeline of how the installation usually takes place:

- Day 1: The first installation day is usually utilized for the first two steps. On this day, the concrete will be cleaned, inspected for damage, all damage repaired, and the concrete will be prepped with a floor grinder or by shot blasting.

- Day 2: The second installation day is when the actual epoxy is typically applied and any customized designs created. By the end of the second day, the final topcoat should be in place.

- After the epoxy floor has been installed, it will need 72 hours to be fully cured and ready for use.

The Benefits of Epoxy Flooring

Epoxy flooring offers many various benefits for home and business owners. These benefits have been proven to save time, money, and effort in maintaining homes or running businesses. Here are the benefits of epoxy flooring:

Durability

Epoxy floors are highly durable flooring solutions designed to take a large amount of stress and wear and tear. Both the compressive strength and tensile strength of epoxy flooring are generally much more robust than concrete. For example, according to epoxy.com, most epoxy floors’ compressive strength is approximately 10,000 psi, compared to the 3,000 psi of standard concrete. Epoxy flooring’s tensile strength comes in at roughly 3,000 psi compared to the 300 psi of traditional concrete. The strength and durability of epoxy flooring protect it from high impacts, rough abrasions, and frequent foot and vehicle traffic. Not to mention, it can support heavy loads and is resistant to scratching.

Resistance

As epoxy flooring is installed seamlessly and has a non-porous surface, it’s resistant to varying liquid substances, such as chemicals and water. Chemicals like fuel, oils, harsh cleaners, and grease are naturally repelled by the non-permeable surface. Water also has no place to seep into the floor. This helps to resist liquid-related damage and staining.

Longevity

The lifespan of epoxy flooring is one of its most known benefits. Most conventional floors are designed to last between 10 and 15 years before needing to be replaced or repaired. Epoxy flooring is built to last twice as long. These floors can last for 25 years or more when properly installed and maintained before they need to be replaced or repaired.

Customization

This benefit is why epoxy flooring has spread so rapidly into the residential sector and more commercial applications. These concrete coatings offer a myriad of colors, patterns, and textures to choose from. They’re highly customizable, as patterns and designs are applied by hand as the floor is poured. This affords the opportunity to create completely custom designs that are unique to the user. The high customizability of epoxy flooring allows it to be versatile enough to handle almost any application.

Ease of Maintenance

Maintaining a floor can be expensive and time-consuming, depending on the flooring material. Epoxy flooring offers home and business owners a low-maintenance flooring solution that will save time, avoiding labor-intensive maintenance routines and expensive cleaning products. Thanks to its seamless installation, epoxy flooring is easy to keep clean, and its resistance helps make spills much easier to clean up.

Environmentally-Friendly

Despite being a chemical-based flooring system, epoxy floors are quite environmentally-friendly. This is partly due to its installation process. In most cases, the only waste produced from an epoxy floor installation is the concrete dust from the floor prep. Other traditional floors require cuts to be made to make the flooring fit the room, producing massive amounts of waste depending on the floor size. Not to mention, if an existing floor is present, that floor must be removed to install the new, conventional floor. However, epoxy flooring can also be installed on certain other flooring materials, such as hardwood and tile, so long as it’s structurally sound and the epoxy can adhere to it. Concrete is always the preferred choice, but it can be installed this way if waste is an issue. Epoxy flooring’s lifespan contributes to its environmentally-friendliness as well. As these floors can last for decades, they create a sustainable flooring solution that will not require frequent replacements or repairs.

Safety

Epoxy flooring benefits safety in a few ways, its customization, slip-resistance, and reflectivity. Customization affects safety in industrial facilities as the floors can be color-coded to mark safe walkways, vehicle paths, and restricted areas. These color-marked areas will not fade or flake away like paint. Epoxy floors are also somewhat slip-resistant, to begin with. They’re no more slippery than concrete. However, if slip-and-fall injuries are an issue in a home or business, many additives can be included that significantly enhance epoxy’s skid-resistance. Reflectivity improves safety thanks to the floor’s glossy finish. The high-gloss finish epoxy flooring has inherently reflects natural and incandescent light. This can drastically enhance visibility in naturally darker areas.

Cost-Efficiency

Epoxy flooring makes for a cost-efficient floor as it can save money in various ways. The first being that it reduces the amount of money needed for maintenance, repairs, and replacements. This flooring system requires minimal tools and products to maintain compared to traditional floors. Its durability prevents it from needing frequent repairs and replacements. The reflective nature of epoxy flooring can also save money by reducing the number of lights required to illuminate a home or business. All of these factors can save on regular expenses for homes or businesses.

Epoxy Flooring Maintenance

Maintaining an epoxy floor is relatively simple. These floors do not require specialized cleaners or expensive tools to maintain them. The only tools needed to maintain an epoxy floor are a broom or dust mop, wet mop, mop bucket, and a pH-neutral floor cleaner. Dust mops are usually preferred as they make removing dirt, dust, and grit a faster process than a traditional broom. As for the pH-neutral floor cleaner, this is preferred, but clear ammonia can be used to clean up messes without adverse effects. According to Epoxy Coating Specialists, dirt and grit should be swept up daily. The floor should be wet mopped with the pH-neutral floor cleaner or clear ammonia weekly, or if the floor becomes heavily soiled. Spot mopping should be performed on an as-needed basis. Soap-based and citrus-based floor cleaners should be avoided. These cleaners can leave a film over the floor that dulls its finish. If a stain does occur, it may require light scrubbing with a non-abrasive scrubbing pad. These floors do not require any kind of wax or floor shine to maintain their finish. If an epoxy floor is starting to look hazy or dull, it doesn’t need wax or polish. Simply clean the floor and mop it to restore its glossy finish.

Epoxy Flooring Costs

The cost to have an epoxy floor installed can vary depending on several factors. These factors include the style of epoxy, size of the space, and complexity of the design. Typically, the larger the room, the less per square foot installation will cost. This is because larger rooms usually have fewer obstacles and transitions to work around. According to Home Advisor, the average cost of a standard epoxy floor ranges from $3 to $7 per square foot. The other epoxy styles generally cost slightly more due to the additional materials and work they require. These epoxy flooring styles will cost roughly $7 to $12 per square foot for installation.